-

Features:

Split Design – Ductile cast iron half shells\Easy handling and fast assembly\Well tested strong locking mechanism – Do not require bolting!\Build in bend restriction\Avoids abrasion of the cable\Protection in free span areas\Supports rock dumping \Environment friendly – No special permits required\The Ductile Cast Iron pipes are certified with chemical and mechanical properties and are fully traceable.

Specifications:

1.Materal: Ductile Iron

2.Size: 40mm-400mm and Per Your Requirement

3.Wall thickness: 8mm-20mm and Per Your Requirement

4. Surface Treatment:Bitumen Painting

5. Package: Iron Pallet or Plywood Case

-

Specifications:

- Material: Ductile iron

- Size: ID50mm-ID400mm or as required

- Wall thickness: 8mm-20mm or as required

- Surface treatment: Asphalt coating (bitumen painting)

We can design and manufacture different sizes of articulated pipes to suit different cable sizes and minimum bending radius requirements. All products can be customized.

-

Bend restrictors are used to protect flexible lines/cable connects from overbending and buckling during their installation or operation phase where static loads are generated. The system comprises a number of interlocking elements that articulate in. At a designed radius the elements mechanically lock to form a semi rigid curved structure that will not move further.

-

Key Benefits:

Split design allows the restrictor to be installed after pipe termination

Easy installation, both onshore and offshore

Lightweight in water, reducing stress on the pipeline

Enhanced durability

We can design and manufacture bend restrictors in various sizes to accommodate different cable diameters. All products are customizable to meet specific requirements.

-

Design features:

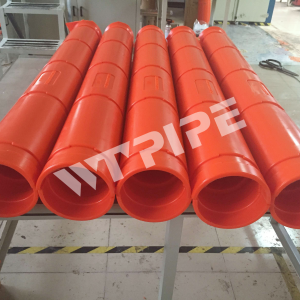

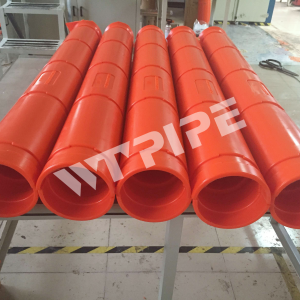

The Polyurethane submarine cable protection tube system is designed to be safe to handle and fast to install.

The design features overlapping and interlocking half shells to provide a close fitting protection around the pipeline, whilst also ensuring alignment during installation. The protective tube can be manufactured from marine grade TPU materials in lengths of up to 1-2 metres.

The Polyurethane submarine cable protection tube system is secured using either corrosion resistant Alloy strapping, placed in recesses on the product during installation. These recesses ensure an even spacing of the strapping along the pipeline without measuring along with a smooth consistent outer diameter.

The flexible characteristics of the materials enable the product to meet the required minimum bend radius of the pipeline.

-

Design Features:

The polyurethane submarine cable protection tube system is safe to operate and fast to install.

The overlapping and interlocking half-shell design provides tight-fitting protection for cables/tubes while ensuring alignment during installation. The protection tube is made of marine-grade TPU material and can be up to 1-2 meters in length. The polyurethane submarine cable protection tube system is fixed using corrosion-resistant alloy belt. During installation, the alloy belts are placed in grooves on the surface of the protection tube and buckle locked. These grooves have a smooth surface and are evenly distributed along the tube, without the need for measurement.

The flexible properties of the material enable the protection tube to meet the minimum bending radius required for the cable/pipe.

We can design and manufacture split conduits in different sizes to suit different cable sizes and diameters. All products can be customized.