Tubo di protezione in poliuretano

Design Features:

The polyurethane submarine cable protection tube system is safe to operate and fast to install.

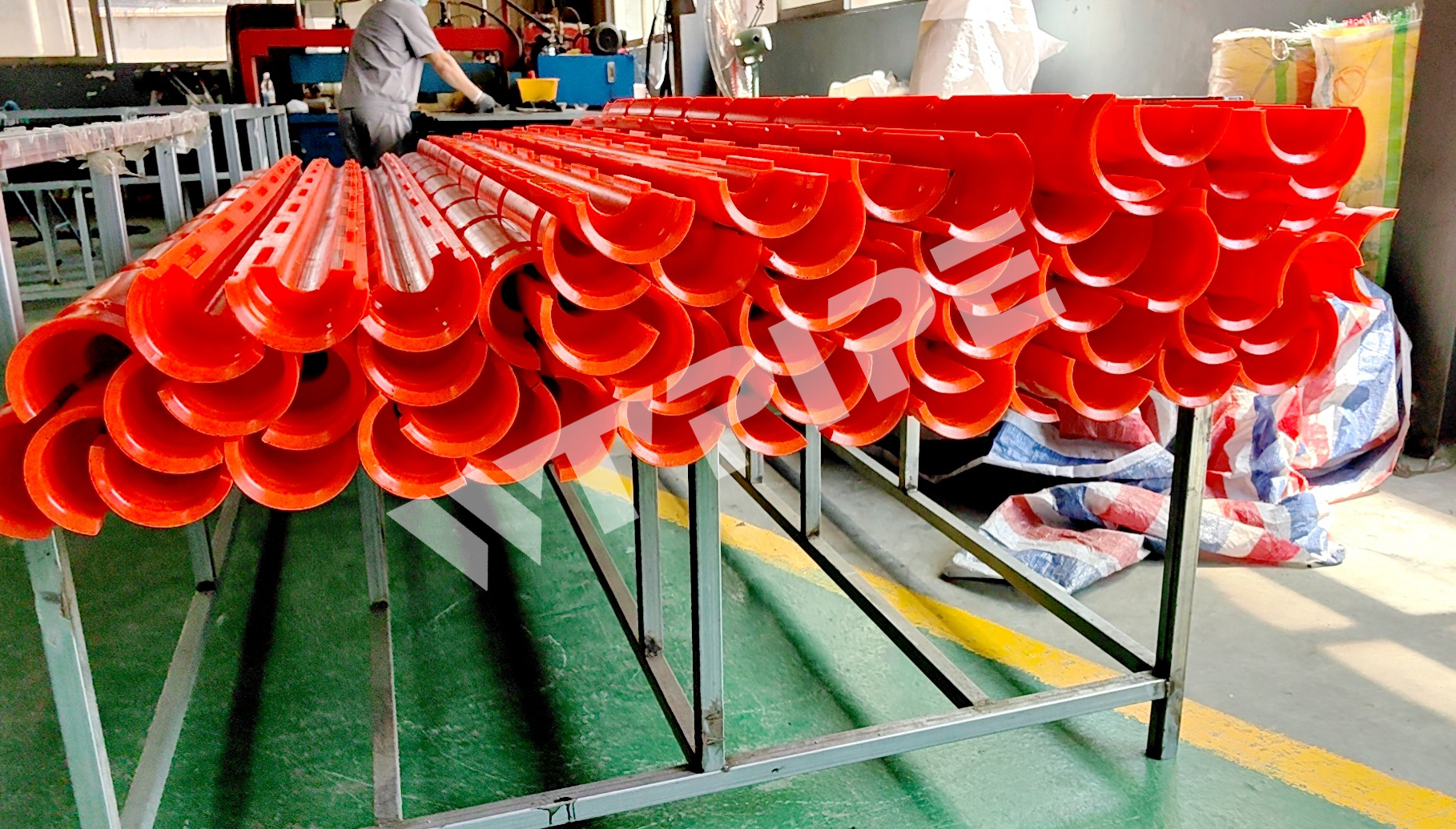

The overlapping and interlocking half-shell design provides tight-fitting protection for cables/tubes while ensuring alignment during installation. The protection tube is made of marine-grade TPU material and can be up to 1-2 meters in length. The polyurethane submarine cable protection tube system is fixed using corrosion-resistant alloy belt. During installation, the alloy belts are placed in grooves on the surface of the protection tube and buckle locked. These grooves have a smooth surface and are evenly distributed along the tube, without the need for measurement.

The flexible properties of the material enable the protection tube to meet the minimum bending radius required for the cable/pipe.

We can design and manufacture split conduits in different sizes to suit different cable sizes and diameters. All products can be customized.

Descrizione

Polyurethane submarine cable protection tube

Product description:

Polyurethane submarine cable protection tube is a protection tube for communication and power cables, which can protect special tubes and submarine cables laid on the seabed from impact and wear. Our company has developed marine polyurethane materials and applied for patents. It uses this material to produce and provide products suitable for the characteristics of various marine projects, including submarine cable protection and offshore oil fields, etc.; polyurethane submarine cable protection tubes have good elasticity, corrosion resistance, hydrolysis resistance, insulation and other characteristics, which can protect cables from the impact of anchors. In addition, polyurethane submarine cable protection tubes have affinity with cables and will not cause puncture damage to cables, and will not wear even in submarine environments where ground subsidence and rock collisions occur. The service life of polyurethane submarine cable protection tubes can reach more than 30 years in the submarine environment where cables and pipelines intersect, and they have excellent wear resistance.

The basic product unit is 1.0-2.0m, which can reduce the man-hours of submarine installation.

Characteristics of material:

Excellent elasticity, corrosion resistance, hydrolysis resistance, insulation.

Polyurethane elastomer protects the cable from the impact of the anchor.

Affinity with the cable means no damage to the cable sheath.

No wear in any marine conditions such as ground or rock settlement.

Excellent anti-corrosion performance in corrosive environments of the seabed environment, durability of more than 30 years, excellent hydrolysis resistance, and excellent surface and dielectric volume.

Processability: The basic unit of 1.0m-2.0m means lighter weight and shorter working time.

No barge crane or auxiliary work boat is required for laying.