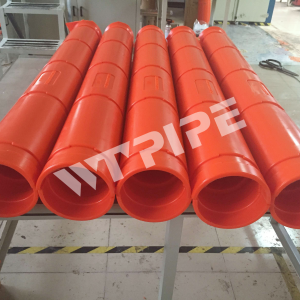

Polyurethane Cable protection pipe

Design features:

The Polyurethane submarine cable protection tube system is designed to be safe to handle and fast to install.

The design features overlapping and interlocking half shells to provide a close fitting protection around the pipeline, whilst also ensuring alignment during installation. The protective tube can be manufactured from marine grade TPU materials in lengths of up to 1-2 metres.

The Polyurethane submarine cable protection tube system is secured using either corrosion resistant Alloy strapping, placed in recesses on the product during installation. These recesses ensure an even spacing of the strapping along the pipeline without measuring along with a smooth consistent outer diameter.

The flexible characteristics of the materials enable the product to meet the required minimum bend radius of the pipeline.

Description

Polyurethane submarine cable protection tube

Description of products:

Polyurethane submarine cable protection tube, a protector of communications and electricity cables, protects special pipes and sea floor cables for sea floor installation from shock and abrasion. We developed a Polyurethane material for marine use and applied for patent of it. Using the material, produces and provides the products suitable for the features of each marine project including a protector for cables installed in the sea floor and marine oil fields;Polyurethane submarine cable protection tube protects cable from shock derived from anchor, due to its excellent elasticity, corrosion-resistance, hydrolysis-resistance and insulation attributes. Moreover, there will be no clothing damage to cable, because of the affinity of Polyurethane submarine cable protection tube with cable, and no abrasion will be found even in the sea floor environment where ground subsidence takes places and rock mass collides. The durability of Polyurethane submarine cable protection tube will last more than 50 years under the sea floor environment with outstanding abrasion-resistance, where cables and pipes cross.

The basic product unit is 1.0-2.0m and the installation working time in the sea floor can be reduced.